Introduction

In the realm of medical device manufacturing, the significance of First Article Inspection (FAI) cannot be overstated. This critical process stands at the forefront of ensuring that every medical device meets the stringent quality and compliance standards set by regulatory bodies. In an industry where the margin for error is virtually non-existent, FAI serves as a crucial checkpoint to safeguard the efficacy and safety of medical devices. It’s not just a procedural formality; it’s a fundamental step in guaranteeing that each product aligns with its intended design and specifications, ultimately ensuring patient safety and product reliability.

FAI goes beyond basic inspection. It embodies a comprehensive evaluation of the first production output, scrutinizing every dimension and specification against design requirements. This rigorous process is vital in medical device manufacturing, where precision is paramount and even the slightest deviation can have significant implications. Through FAI, manufacturers can identify potential production issues at an early stage, preventing costly mistakes and ensuring that subsequent production runs are flawless.

In this detailed exploration, we delve into the nuances of FAI in the medical device industry. We will examine its objectives, the regulatory landscape it operates within, and the best practices that ensure its effectiveness. By highlighting the challenges offering solutions, and showcasing a real-world success story, we aim to underscore the indispensable role of FAI in medical device manufacturing. Additionally, we will explore how advanced metrology techniques, a speciality of Verus Metrology Partners, can further enhance the FAI process, ensuring the highest standards of quality and compliance.

Understanding FAI

Definition and Objectives

First Article Inspection (FAI) in the medical device industry is a critical and comprehensive process tailored to ensure that a new product or a change in the manufacturing process meets stringent quality and compliance requirements. This inspection is not merely a routine check but a pivotal step in the life cycle of medical device production. It involves a meticulous examination of the first batch of products from a new or updated production line, ensuring they align perfectly with the design specifications and engineering drawings.

The primary objectives of FAI are multi-fold. Primarily, it serves to validate the manufacturing process, confirming that the product meets all design, quality, and regulatory standards. It’s a process that offers manufacturers in the medical device sector a high degree of assurance about the reliability and precision of their production processes, which is crucial in an industry where products directly impact patient health and safety.

Regulatory and Quality Assurance Aspects

FAI is deeply entrenched in regulatory compliance and quality assurance. It’s a process rigorously followed to meet internal quality standards as well as external regulatory requirements. Given the critical nature of medical devices, the industry is heavily regulated, with agencies like the FDA and European Medical Device Regulation (MDR) setting exacting standards. FAI is a key component in meeting these standards, providing documented evidence that the products are manufactured according to the approved design and are fit for their intended use.

FAI’s role in quality assurance is equally significant. It ensures that each new product or process modification does not introduce any unforeseen issues or deviations from the set quality standards. This process aids in identifying and rectifying potential problems at the earliest stage, preventing costly rework, and delays, and, most importantly, ensuring patient safety.

The FAI Process

Verus Metrology Partner’s approach to FAI comprises several key steps:

- Preparation: In this initial stage, Verus Metrology Partners works closely with clients to prepare for the FAI. This involves understanding the product design, quality control parameters, and manufacturing process. Expert consultation is provided to ensure that all aspects of the product and process are aligned for a successful FAI.

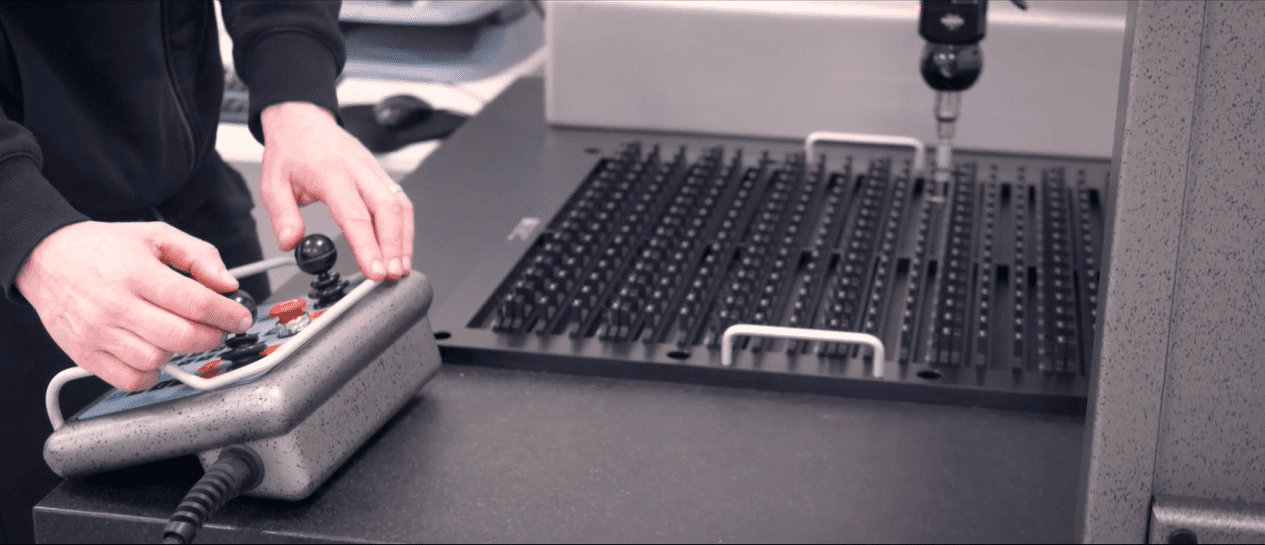

- Inspection: The actual inspection is a detailed process where a batch of products from the new or updated line is examined. This inspection is conducted using advanced and calibrated equipment, operated by qualified metrology engineers. The inspection follows a pre-determined plan, focusing on ensuring that the products meet the original specifications and engineering drawings.

- First Article Inspection Report (FAIR): Post-inspection, a comprehensive FAIR is generated. This report is crucial as it indicates a pass or fail status for the inspected products. A pass signifies the products meet all requirements, allowing manufacturing to continue confidently. In case of a failure, it pinpoints the specific variances and discrepancies, enabling manufacturers to take immediate corrective action.

FAI is a vital process in the medical device industry, deeply rooted in ensuring compliance, quality, and patient safety. It’s a process that Verus Metrology Partners specialises in, providing manufacturers with the assurance and documentation needed to proceed confidently with their production processes.

Best Practices in FAI

First Article Inspection (FAI) is a pivotal step in medical device manufacturing, ensuring that new products or process changes meet stringent quality and compliance standards. Verus Metrology Partners, with its specialization in FAI services, emphasizes the importance of a meticulous and structured approach to this process. Here are some best practices for conducting an effective FAI in the medical device sector:

- Preparation is Key: The groundwork laid during the early stages of FAI is crucial. It involves understanding the product design, quality control parameters, and manufacturing processes. Verus provides consultation services during this stage to ensure that the product design, quality control, and manufacturing teams receive the necessary metrology support and expert advice. This comprehensive preparation aids in aligning all aspects of the project towards a successful FAI.

- Detailed Inspection Process: Conducting the inspection involves a thorough examination of a randomly selected batch of products from the new or updated production line. This step is carried out using established FAI procedures, ensuring that every aspect of the product matches the original specifications and engineering drawings. This process is completed using advanced, fully calibrated inspection equipment operated by qualified metrology engineers, ensuring the highest levels of accuracy and precision.

- Comprehensive First Article Inspection Report (FAIR): Following the inspection, a detailed FAIR is provided. This report outlines the results of the inspection, indicating whether the inspected parts match the design requirements. A ‘pass’ in the FAIR allows the continuation of the manufacturing process, providing assurance of the process’s reliability. In case of a ‘fail,’ the report details the variances and discrepancies identified, enabling manufacturers to undertake necessary corrective actions.

- Adherence to Regulatory Standards: It’s essential to align the FAI process with the prevailing regulatory standards. Verus ensures that its FAI services meet both internal quality standards and compliance requirements, particularly in the heavily regulated medical device industry.

- Utilizing Advanced Metrology Techniques: The use of state-of-the-art metrology equipment and techniques further enhances the effectiveness of the FAI process. This involves leveraging the latest advancements in metrology to ensure precise and reliable inspection results.

By following these best practices, manufacturers in the medical device industry can ensure that their products meet the necessary quality and compliance benchmarks. Verus’s expertise in FAI plays a significant role in advancing these practices, offering manufacturers a reliable and efficient pathway to validate their production processes and product quality.

Challenges and Solutions in FAI

First Article Inspection (FAI) is a complex and critical process in the medical device manufacturing industry, ensuring that new products or significant changes to the manufacturing process meet stringent quality and compliance standards. Here we explore some of the common challenges encountered during FAI and the effective solutions provided by Verus Metrology Partners.

Common Challenges

- Complexity in New Product Introductions (NPIs): Introducing a new medical device product involves numerous complexities. These include ensuring the product meets all design specifications, quality standards, and regulatory requirements.

- Changes in Design and Manufacturing Process: Any design change or update in the manufacturing process necessitates a thorough re-verification to ensure continued compliance and quality. This could involve new tooling, equipment, materials, or relocating the production line.

- Restarting Production Lines: When a dormant production line is restarted, it poses challenges in terms of ensuring that the manufacturing process still meets the required standards.

- Customer Requests in Contract Manufacturing: Contract manufacturers often face FAI requests from their clients, adding another layer of complexity to their operations.

Verus Metrology Partner’s Solutions

- Experienced and Qualified Engineers: Verus employs a team of qualified and experienced engineers who are adept at handling the complexities of FAI. Their expertise ensures that FAI is conducted effectively, regardless of the intricacies involved.

- Advanced Inspection Equipment: The company utilizes advanced and fully calibrated inspection equipment, operated by skilled metrology engineers. This equipment is crucial for carrying out detailed inspections, especially when dealing with intricate medical device components.

- Comprehensive FAI Reports: Verus provides an impartial and comprehensive First Article Inspection Report (FAIR) after the inspection. This report outlines whether the inspected parts match the design requirements according to the original specifications and engineering drawings. The report indicates a pass or fail, offering clear guidance on whether the manufacturing process can continue or if there are variances that need to be addressed.

- Handling Diverse FAI Scenarios: The company is equipped to handle a wide range of scenarios requiring FAI, such as NPIs, design changes, manufacturing process changes, factory relocations, restarting production lines, and customer requests. This versatility ensures that products remain in compliance with FDA, European, and other medical device regulations.

First Article Inspection, while challenging, is an integral part of medical device manufacturing, ensuring products meet the highest standards of quality and compliance. Verus Metrology Partner’s approach to these challenges involves leveraging its skilled team, advanced equipment, and comprehensive reporting, ensuring that its clients navigate the complexities of FAI with confidence and precision.

The Role of Advanced Metrology in FAI

In the world of First Article Inspection (FAI), the role of advanced metrology cannot be understated. Verus Metrology Partners, with its global reach and innovative approach, has been at the forefront of enhancing metrology laboratories and inspection processes. The company’s expertise in dealing with high-quantity, challenging-to-measure, yet critically important medical device parts, has set a new benchmark in the MedTech, Pharmaceutical, and Personal Care industries.

Verus Metrology Partner’s commitment to automated and intelligent metrology inspection systems is transforming the landscape of part measurement. By addressing and resolving everyday metrology challenges, their state-of-the-art metrology inspection fixtures are revolutionizing measurement capabilities. These advancements are not just incremental improvements; they represent a significant leap forward in the field, driving part measurement innovation for years to come.

Furthermore, Verus’s structured training program is designed to equip engineers with the necessary knowledge and skills for advanced metrology inspection routines. This training is particularly vital for handling difficult-to-measure parts at high volumes. The program focuses on technical skills such as routine programming and metrology methodology, ensuring that quality teams and projects are well-equipped to handle the complexities of advanced metrology in FAI.

The integration of advanced metrology in FAI processes significantly enhances inspection accuracy, efficiency, and reliability, which are crucial in the medical device manufacturing sector. Through innovative solutions and expert training, Verus is leading the way in advancing metrology practices, ensuring that its clients can meet and exceed the demanding standards of quality and compliance in the industry.

Conclusion

First Article Inspection (FAI) in medical device manufacturing is not just a procedural step but a cornerstone of quality assurance and regulatory compliance. The role it plays in ensuring the safety, reliability, and effectiveness of medical devices cannot be overstated. As the medical device industry continues to evolve, so does the complexity of its products and the stringency of its regulations, making FAI an indispensable part of the manufacturing process.

Verus Metrology Partners, through its commitment to advanced metrology and innovative solutions, has significantly contributed to enhancing the FAI process. The company’s continuous review of its capacity, skillset, equipment, and partnerships ensures that it remains at the forefront of the metrology field, meeting and exceeding the dynamic needs of its clients. With over 250 success stories worldwide, Verus has demonstrated its ability to deliver quality metrology services, advancing the metrology processes and technology for its clients.

In the ever-evolving landscape of medical device manufacturing, FAI remains a vital tool for manufacturers. It serves as a guarantee of quality and compliance, ensuring that medical devices entering the market are not only fit for their intended use but also meet the highest standards of safety and efficacy. As a leader in metrology solutions, Verus Metrology Partners continues to play a pivotal role in advancing these processes, ensuring the medical devices supplied to the market are robust, reliable, and of great value. Read more about the details of our FAI services and request a quote today.