At Verus Metrology Partners, we believe that precision and sustainability go hand in hand. As a trusted provider of metrology solutions for FMCG and medical device manufacturers, we understand that improving quality control not only reduces defects but also minimizes material waste—both within our operations and for our clients.

Sustainability in manufacturing is not just about compliance; it is about designing smarter, working efficiently, and reducing environmental impact at every stage. That is why we have taken key steps to embed sustainability into our operations, including:

- Investing in solar energy to power our facility

- Achieving ISO 14001 certification for Environmental Management Systems

- Standardizing fixture parts to reduce material waste

- Offering fixture repairs and promoting long-term use over a throwaway culture

- Recycling aluminum waste to support circular economy practices

- Helping clients reduce material waste with high-precision components

How We’re Making a Difference

1. Reducing Waste Through Standardization and Repair Services

In an industry where customization is key, we have found a way to balance precision engineering with sustainability. By standardizing key fixture components, we:

- Reduce material waste by reusing common fixture parts

- Optimize production efficiency, lowering resource consumption

- Offer scalable solutions that are both cost-effective and sustainable

We also actively promote repair and refurbishment over the typical throwaway culture. Instead of discarding metrology fixtures after wear and tear, we provide repair services and part replacements, extending their lifespan and preventing unnecessary waste.

James McElroy, Lean Project Coordinator, emphasizes the importance of sustainability in our lean initiatives:

“At Verus, sustainability is not just an add-on; it is embedded into how we design, build, and maintain our fixtures. By continuously improving our processes and reducing waste, we create long-term value for our clients while supporting a more sustainable manufacturing industry.”

“At Verus, sustainability is not just an add-on; it is embedded into how we design, build, and maintain our fixtures. By continuously improving our processes and reducing waste, we create long-term value for our clients while supporting a more sustainable manufacturing industry.”

2. Helping Clients Minimize Waste with High-Quality Components

Every rejected component in FMCG and medical device manufacturing results in wasted materials, often plastic or other non-recyclable materials. Our high-precision metrology solutions enable manufacturers to:

- Achieve superior quality control, reducing the number of defective parts

- Optimize production processes, leading to less material waste

- Enhance sustainability efforts by improving first-time yield rates

By providing customized, durable, and precise metrology fixtures, we help our clients reduce overall scrap rates and material consumption, leading to a more sustainable manufacturing process.

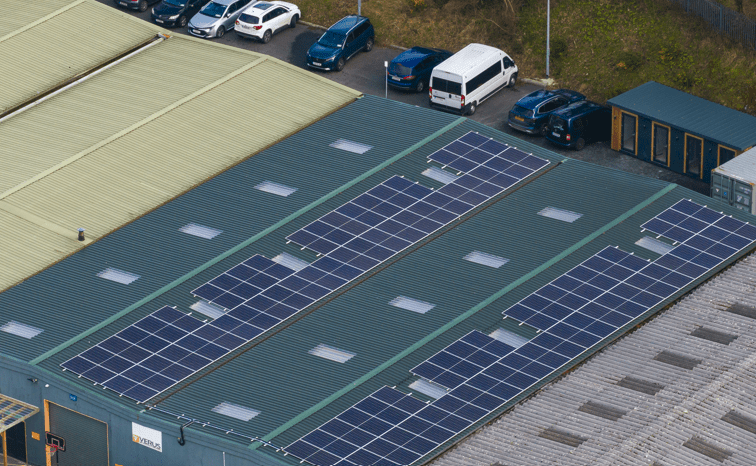

3. Investing in Renewable Energy: Solar-Powered Operations

As part of our commitment to a greener future, we have invested in solar panel technology to reduce our dependence on non-renewable energy sources. This initiative allows us to:

- Power our operations with clean, renewable energy

- Reduce our carbon footprint and environmental impact

- Contribute to a more sustainable supply chain for our clients

4. ISO 14001 Certification: Commitment to Environmental Responsibility

We are proud to have earned ISO 14001 certification, an internationally recognized standard for environmental management systems. This milestone highlights our commitment to:

- Sustainable resource management

- Continuous improvement in environmental impact reduction

- Compliance with global sustainability standards

According to Ronan O’Hara, our Quality, Health & Safety Lead,

“Achieving ISO 14001 is a major step forward in our sustainability journey. It reinforces our commitment to responsible manufacturing practices and environmental protection.”

“Achieving ISO 14001 is a major step forward in our sustainability journey. It reinforces our commitment to responsible manufacturing practices and environmental protection.”

5. Recycling Aluminum Waste to Support a Circular Economy

Aluminum is a core material in our fixture manufacturing, and we ensure that all aluminum waste is recycled rather than discarded. By repurposing aluminum waste, we:

- Reduce raw material consumption and environmental impact

- Contribute to a circular economy, minimizing waste output

- Lower our overall production footprint, making our solutions more sustainable

6. Aligning with Ireland’s Net Zero Goals

Ireland has set ambitious targets to reach net-zero emissions by 2050, with key milestones such as a 51 percent reduction in greenhouse gas emissions by 2030 and a strong focus on renewable energy and waste reduction. At Verus Metrology Partners, we are committed to supporting these national goals by:

- Reducing our reliance on non-renewable energy through solar power

- Implementing sustainable manufacturing practices that reduce material waste

- Helping FMCG and medical device manufacturers improve efficiency and sustainability

Our efforts align with Ireland’s Climate Action Plan 2024, ensuring that we contribute to a more sustainable industrial sector while maintaining the highest standards of precision and quality. To learn more about Ireland’s net-zero goals, visit Ireland’s Climate Action Plan 2024.

7. Sustainability Through Smarter Manufacturing

Sustainability is not just about meeting regulations; it is about setting new standards for efficiency, quality, and environmental responsibility.

“At Verus Metrology Partners, we believe that precision and sustainability must go together. By improving quality control and reducing waste—both in our operations and for our clients—we help create better, more sustainable manufacturing processes that deliver long-term value.”

— Andrew Hodson, CEO

— Andrew Hodson, CEO

Looking Ahead: Our Sustainability Goals

As we move forward, we remain dedicated to:

- Expanding our use of renewable energy sources

- Innovating even more efficient metrology solutions to support waste reduction

- Strengthening collaborations with sustainable suppliers and partners

Join Us on Our Sustainability Journey

We invite our partners, clients, and industry leaders to collaborate in driving sustainability forward. If you are looking for ways to improve quality control while reducing environmental impact, let’s start the conversation.

Contact us to learn more about our sustainability initiatives.